This article is about installing electric winches on Versatower ham radio masts.

I have installed electric winches on several Versatower ham radio masts including a P45, two P60HDs and a P80 and all work as expected.

My approach is low cost and has proven to be both safe and reliable over six years of operation at home and at various contest sites on our mobile towers.

Winch sizes

There is a lot of talk about the size of an electric winch required to luff or raise/lower a Versatower mast. Let us remember that a standard 40ft, 45ft or 60ft mast (P40, P45, P60) uses a Fulton K1550 winch for luffing and raising/lowering. These winches are rated at 1550lbs.

P60HD (60ft heavy duty), P80 (80ft) and P80HD (80ft heavy duty) masts that I have worked on have the larger Fulton K2550 and are rated at 2550lbs.

Many people talk about using what is, in my opinion, excessively large electric winches – you really don’t need something rated to pull 8000, 10000 or 12000 lbs of load and it could be counter productive if something jams because you’re more likely to snap the rope causing a major collapse compared with a more modest motor which is likely to stall.

Rope type and size

I have upgraded all of my Versatowers to 6mm 16×9 Fibre Core (FC) galvanised steel wire rope – 16×9 FC is flexible and best suited the the small radius bends around the sheaves (pulleys) and the fibre core provides additional flexibility while also retaining lubrication better in the long term.

The Safe Working Load (SWL) for 6mm 16×9 FC is 400Kgs and breaking load is 2000Kgs. In normal operation the load (mast sactions, head unit, rotator and antennas) are spread across two runs of the rope meaning that you a mechanical advantage of 2:1 and 800Kg should be a safe load and you shouldn’t have a problem.

Please do not be tempted to use Stainless Steel rope in the belief that it is better in this application – it is less flexible and more brittle and doesn’t go round tight bends as well as malleable galvanised steel and also has a lower maximum load rating.

The luffing ropes on our smaller towers are 6mm 16×9 FC and on the larger towers are 8mm 16×9 FC.

Choice of Electric Winch

Where I have replaced a Fulton manual winch with an electric unit I use the Superwinch Terra 45. The Superwinch Terra 45 is designed for All Terrain Vehicles (ATVs) and is rated at 4500lbs (2067Kg) and is supplied with 5.6mm galvanised rope with a hook/catch on the end – which I discard (see below).

I chose the Terra 45 because:

- its compact

- its rated at nearly twice a Fulton K2550

- it fits directly on to the two parallel bars on a Versatower

- it doesn’t have a handle that is easy to move to the ‘free spool’ position (dangerous)

- its well made

- spares are available

- its cost effective

Example installation

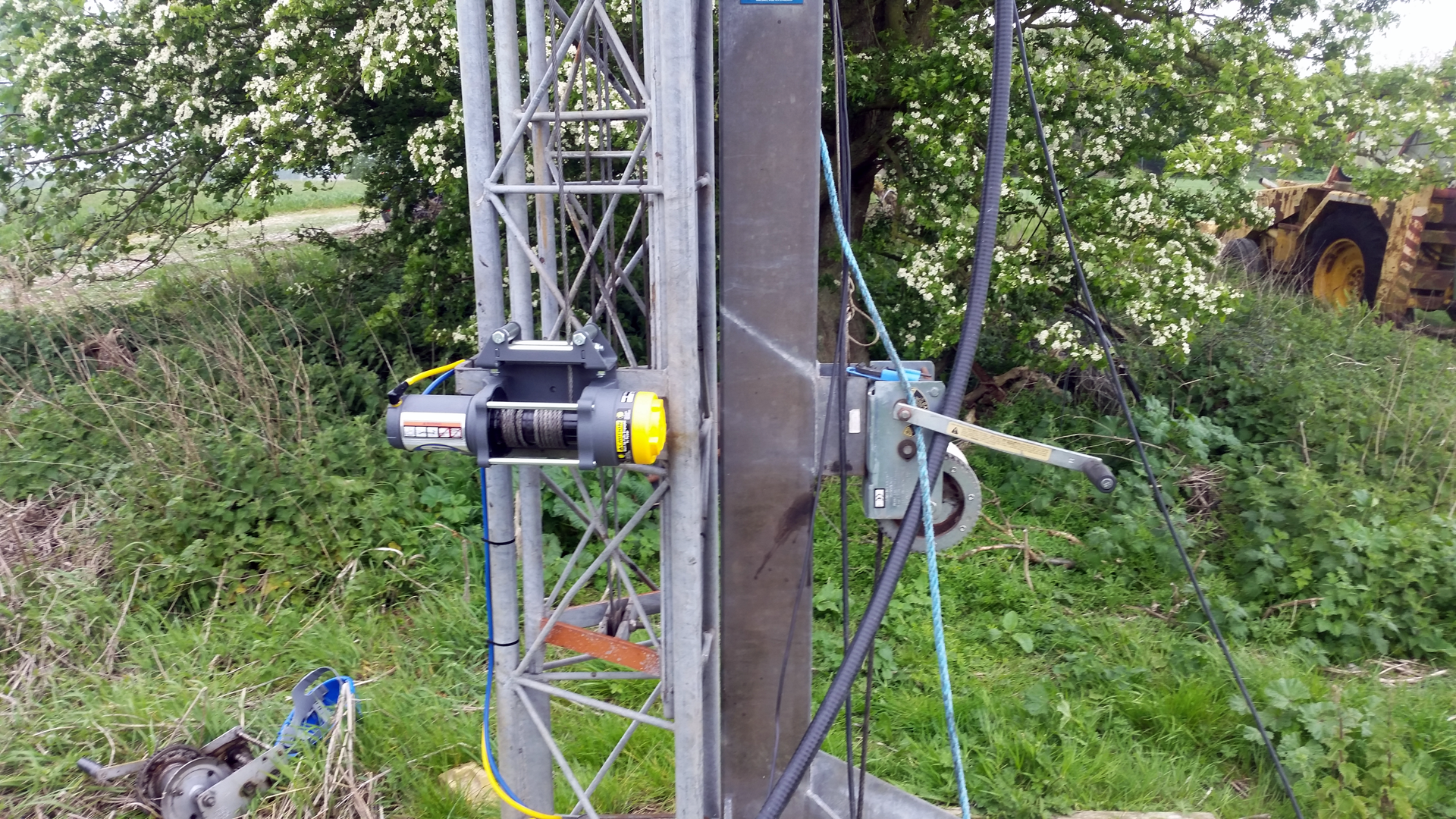

The photograph below is of the installation on the BlackSheep fixed BP60HD (heavy duty) Versatower at our contest site in Kent:

Superwinch Terra 45 installed on BP60HD in Spring 2017

On this mast we still use a Fulton K2550 for luffing and thge luffing rope is 8mm.

Installation

The Terra 45 will fit directly on to the two horizontal bars on the Versatower such that the raising rope comes over the top sheave directly down the side of the tower, through the fairlead (supplied with the winch) and onto the spool – like this:

Close-up of Terra 45 installation on BP60HD

Installation procedure:

- make sure the winch is located approx 20% left of centre so that the yellow hub clears the vertex of the mast (see photo above)

- measure the hole distances as per the installation manual

- dot punch the horizontal bars (4 locations)

- drill a pilot hole (4 locations) using a sharp 4mm HSS bit

- re-drill each hole to 9.0mm diameter

- de-burr the holes with an M13 bit

- use 4 off M8 x 30mm 8.8 tensile bolts, 4 off M8 flat washer and 4 off M8 spring washer through the tower flats from behind, through the another 4 off M8 flash washers (packing washers) between the bars and the fairlead plate, then the bolts then engage in the M8 captive nuts in the winch casting.

I recommend using 4 x flat washers between the Versatower flat bars and the back of the fairlead plate as spacers because there’s a weld that joins the two flats and its often uneven and can cause the fairlead plate to rock back and forth otherwise – you’ll see what I mean if you attempt to assemble it without the packing washers.

I removed the 5.6mm steel rope supplied with the winch from the spool and used the 6mm 16×9 FC galvanised rope that was already on the tower – it fits in to the spool with a chock that is secured by two Allan head grub screws.

Wiring

I use the supplied yellow/blue cable, chop it down a bit and fit an Anderson SB50 PowerPole connector as a break jack. You can use the reversing contactor and hand-held up/down (in/out) control if you wish or alternatively buy a set of 16mm jump leads, chop them in half and fit an Anderson PowerPole to them and just chuck them on to a battery one way round or the other for up and down – this gets you a spare pair of chunky crock clips.

Maintenance

I strongly recommend lubricating the ropes, sheaves and winch every 6 months using a quality spray on wire rope and chain lube such as FIXT Wire Rope And Chain Lubricant:

This can be found on Ebay and Amazon.

Costs

We paid about £220-230 each for our winches – they appear to have gone up (due to changes in the exchange rate). Best price I could find at the time of writing (July 2017) was £263.99 on Ebay – your mileage may vary.

Make sure you buy the variant with the steel rope and not the synthetic rope – I believe the spool is different.

Mike G8TIC/M0VHF/M0BAA/G8T